What is Lead Time in Supply Chain?

Lead time in the supply chain is the duration from when a product is ordered until it is delivered to the customer. This period includes various stages such as raw material acquisition, order processing, manufacturing, assembly, and packaging. Understanding lead time definition is crucial for maintaining the efficiency of supply chain management.

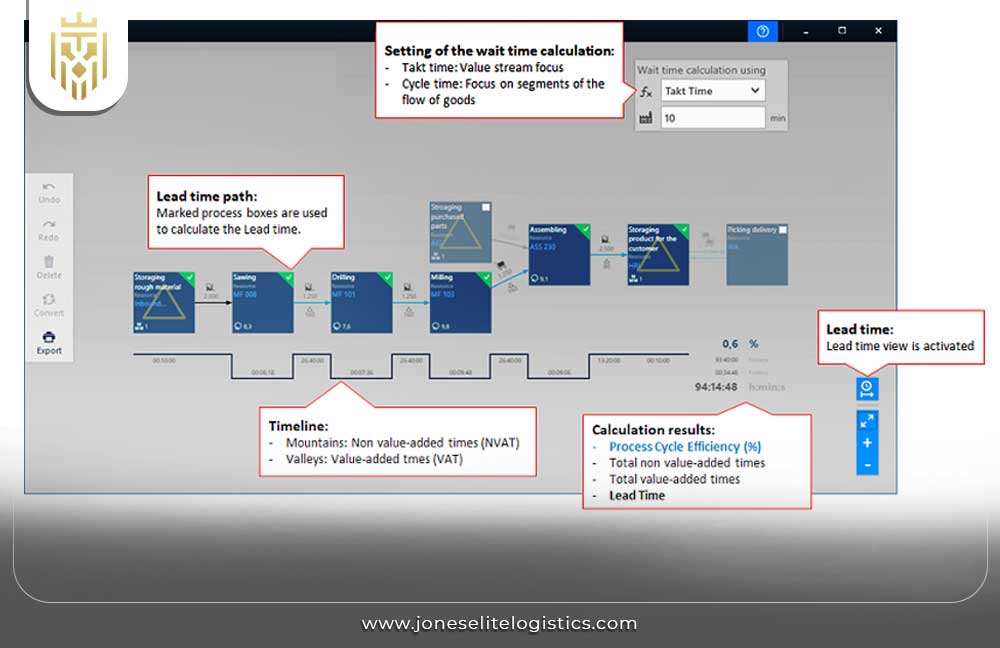

How to Calculate Lead Time?

Lead time can be calculated through different methods, such as measuring the time from order request to delivery date, considering supply delays plus reordering delays, or breaking it down into procurement and shipping lead times. Calculate lead time accurately to ensure effective supply chain management and timely product delivery.

Why is it important to measure lead time in the supply chain?

Measuring lead time is vital for several reasons: it enhances customer satisfaction, provides a competitive advantage, improves operational efficiency, and facilitates better cash flow management. Accurate lead time measurement also aids in effective decision-making and supply chain collaboration.

Types of Lead Time in the Supply Chain:

Different types of lead time include product lead time, supplier lead time, customer lead time, and manufacturing lead time. Each type impacts overall supply chain efficiency, highlighting the need to understand various lead time definitions to optimize performance.

Supplier Lead Time:

Supplier lead time is the period required for a supplier to deliver goods to the customer after receiving an order. This aspect of lead time affects the overall speed and efficiency of the supply chain process.

Manufacturing Lead Time :

Manufacturing lead time encompasses the time needed to complete the production process, including preprocessing, processing, and post-processing stages. Efficient management of this lead time is crucial for optimizing supply chain operations.

Customer Lead Time:

Customer lead time is the time it takes to fulfil a customer’s order from the moment of request to delivery. This metric reflects the overall service speed and impacts customer satisfaction and supply chain performance.

Product Lead Time:

Product lead time is the total time from order placement to product delivery, including stages like manufacturing, assembly, and packaging. Reducing product lead time can significantly enhance the efficiency of the supply chain.

How to Reduce Lead Time in Supply Chain?

To reduce lead time in the supply chain, consider optimizing processes, improving measurement accuracy, and implementing strategies to streamline operations. Techniques such as process automation, lean manufacturing, and reducing product complexity can effectively shorten total lead time and boost efficiency.

Accurately Measure all Supply Times within Ranges:

Accurate measurement of all supply times helps identify delays and areas needing improvement. This practice leads to reduced lead times and enhanced supply chain performance by addressing inefficiencies.

Process Automation:

Process automation minimizes manual tasks, speeds up production, and reduces errors. By streamlining operations, automation helps in achieving reduced lead times and increased overall efficiency in the supply chain.

Lean Manufacturing:

Lean manufacturing focuses on eliminating waste and optimizing processes. By concentrating on value-adding activities and removing non-essential steps, lean practices can significantly shorten lead times and enhance supply chain efficiency.

Reduce Product Complexity:

Simplifying product design and components accelerates the manufacturing process, lowers error rates, and shortens lead times. Making the production process more straightforward and efficient helps in achieving better performance in the supply chain.

FAQs

1) What is Lead Time in the Supply Chain?

Lead time in the supply chain is the span from when a product is ordered to its delivery, encompassing raw material acquisition, order processing, manufacturing, assembly, and packaging stages.

2) What are the types of Lead Time in the Supply Chain?

Various types of lead time include product, supplier, customer, and manufacturing lead times. Each affects supply chain efficiency, underscoring the importance of understanding different lead time definitions for performance optimization.

3) Why is it important to measure lead time in the supply chain?

Measuring lead time is crucial as it boosts customer satisfaction, offers a competitive edge, enhances operational efficiency, and improves cash flow management. Accurate measurement also supports better decision-making and effective supply chain collaboration.

4) How can Lead Time Reduction affect business?

Lead time reduction can significantly impact a business by improving operational efficiency, reducing costs, and enhancing customer satisfaction. Shorter lead times enable faster response to market demands, streamline production processes, and strengthen competitive advantage.