What is Supply Chain Visibility?

Supply Chain Visibility refers to the ability to track product movement and data across supply chains. It enables companies to have real-time insights into their logistics, inventory, and overall processes. By ensuring transparency, companies can better manage potential disruptions and build greater resilience in their operations.

Why Use Supply Chain Visibility?

Supply chain visibility helps companies enhance customer experience and meet demand accurately. It minimizes disruptions by providing transparency into products at each stage, improving the ability to track delays and reduce costs. This ability also supports risk management, fosters resilience, and ensures compliance with regulations, offering competitive advantages.

Types of Supply Chain Visibility:

Types of supply chain visibility include inventory visibility, supplier and vendor visibility, order details visibility, demand and supply visibility, and logistics visibility, all providing real-time insights to optimize operations, improve decision-making, and enhance overall efficiency.

Inventory Visibility:

Inventory visibility helps companies monitor the real-time status, quantity, and location of products across the supply chain. This ability prevents overstocking and stockouts, leading to better demand forecasting and resource allocation. By tracking inventory, supply chain visibility improves resilience and strengthens supplier collaboration.

Supplier and Vendor Visibility:

Supplier visibility tracks the products and operations of suppliers to help manage potential disruptions and reduce risks. Vendor visibility supports companies by facilitating better communication, collaboration, and transparency across their networks. This increases the resilience of supply chains and improves operational efficiency.

Order Details Visibility:

Order visibility provides companies with insights into the status of each order, from shipment updates to delivery times. It helps track products, manage customer expectations, and reduce dissatisfaction. This ability ensures timely delivery and enhances overall supply chain performance, making it crucial for end-to-end transparency.

Demand and Supply Visibility:

Demand and supply visibility enables companies to balance customer demand with available inventory and supply levels. This ability prevents supply chain disruptions by ensuring resources are efficiently allocated. It also enhances customer satisfaction by better aligning supply with demand expectations.

Logistics Visibility:

Logistics visibility involves real-time tracking of a product’s journey through the supply chain, from shipment to delivery. This ability helps companies streamline transportation and delivery processes by identifying potential disruptions and improving overall efficiency. It ensures transparency throughout the logistics operation, strengthening resilience.

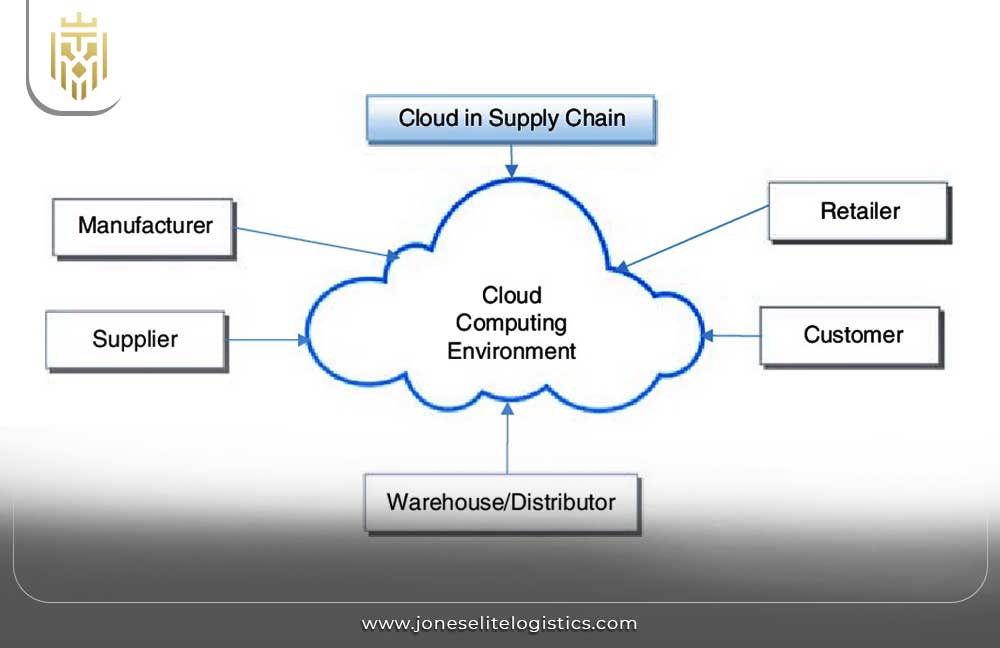

What are the Technologies for Supply Chain Visibility?

Key technologies enhancing supply chain visibility include platforms for tracking, cloud-based communication tools, and inventory management software. These systems offer real-time transparency, helping companies map their entire supply chains and monitor supplier performance. Supply chain control towers further centralize the data, offering a comprehensive view to reduce disruptions.

How to Achieve a Highly Visible Supply Chain?

To improve supply chain visibility, companies can automate processes, enhance inventory management, and collaborate with suppliers. Investing in technology that tracks products and frequently communicating with partners ensures transparency. Offering real-time tracking and gathering customer feedback increases visibility and minimizes potential disruptions.

FAQs

1) What is Supply Chain Visibility?

Supply chain visibility refers to the ability to track products and information across the supply chain in real-time, offering transparency into logistics, inventory, and operations, enhancing efficiency, and minimizing potential disruptions.

2) What are the Types of Supply Chain Visibility?

Types of supply chain visibility include inventory visibility, supplier and vendor visibility, order details visibility, demand and supply visibility, and logistics visibility, each providing real-time insights to optimize operations and enhance transparency and resilience.

3) What are the Technologies for Supply Chain Visibility?

Technologies include supply chain visibility platforms, cloud-based communication tools, inventory management software, supply chain mapping, data integration, and supply chain control towers, enabling companies to track products and maintain operational transparency.

4) How to Achieve a Highly Visible Supply Chain?

Achieve supply chain visibility by automating processes, improving inventory management, collaborating with suppliers, investing in technology, mapping the supply chain, offering real-time tracking, and gathering customer feedback to enhance transparency and prevent disruptions.