There’s a rumour that the infamous American gangster, Al Capone, had campaigned for expiry dates on milk bottles after a relative fell ill from drinking sour milk unknowingly. This highlights a key challenge in the milk supply chain: temperature changes disrupt production and increase spoilage risks due to bacterial growth. Cold chain solutions and temperature control are vital for maintaining product integrity, ensuring the dairy supply chain can withstand climate challenges and deliver safe milk.

An Overview of the Milk Supply Chain:

The milk supply chain integrates production, transport, processing, and packaging, with each stage adding value to milk products. Inputs like raw materials drive this process, supported by effective manufacturing logistics and production logistics. Efficient milk run logistics consolidate supplier loads to optimize dispatch routes, reduce costs, and minimize environmental impact, aligning with principles of green supply chain management.

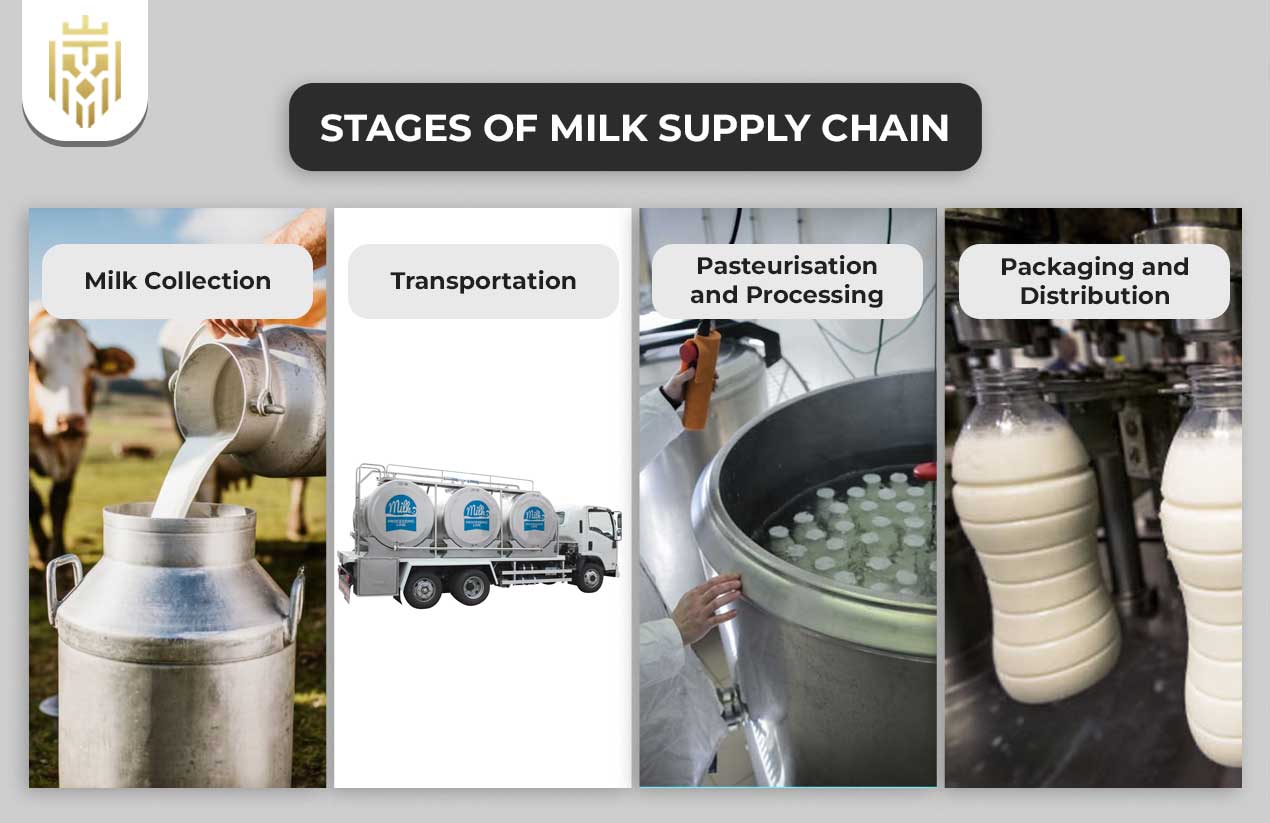

Stages of Milk Supply Chain:

The milk supply chain involves milk collection, transportation, pasteurisation and processing, and packaging and distribution. Efficient milk run logistics, production logistics, and cold chain management ensure quality, sustainability, and timely delivery to consumers.

Milk Collection:

In the milk supply chain, milk is collected through systematic steps, including milking, cooling, and transportation. Maintaining hygiene at collection centres and using cold chain solutions preserves quality. Timely processing within four hours prevents spoilage. This stage relies on supply chain management in agriculture to streamline activities, ensuring that production logistics and manufacturing logistics uphold quality and extend product shelf life.

Transportation:

The supply chain of milk industry involves transporting milk from farms to processing plants and retailers. Milk run logistics with optimised routes reduce transit times, costs, and carbon emissions, enhancing the dairy sector’s green supply chain management efforts. Chilled transportation, supported by dispatch logistics, preserves milk quality by maintaining temperatures below 4°C, ensuring fresh delivery to end consumers.

Pasteurization and Processing:

Pasteurization and processing in the milk supply chain ensure safety and enhance product quality. Steps like filtering, homogenization, and packaging rely on efficient production logistics and manufacturing logistics to maintain consistency and taste. These activities align with green supply chain management, ensuring sustainable practices and extending shelf life, critical for the dairy supply chain to meet consumer expectations.

Packaging and Distribution:

In the supply chain of milk industry, packaging involves LDPE (low density polyethylene), HDPE (high density polyethylene), and aseptic methods for sustainability. Distribution leverages dispatch logistics for efficient delivery to retailers and consumers. By incorporating green supply chain management practices, the milk supply chain ensures products are packaged, transported, and stored with minimal environmental impact, maintaining safety and freshness throughout the process.

Challenges of Milk Supply Chain:

The milk supply chain faces challenges like rising temperatures affecting production, high transportation costs from refrigerated logistics, and pilferage. Efficient milk run logistics, cold chain management, and green supply chain management practices help mitigate these issues.

Raising Temperature:

Changes in temperature cause milk supply chain disruptions through reduced milk production (up to 10% per 1°C change) and increase in risk of spoilage due to bacterial activity. Cold chain solutions and temperature control are part of effective supply chain management in agriculture and the dairy supply chain can withstand climate challenges and maintain product integrity.

High Transportation Costs:

High fuel, maintenance and route planning inefficiencies make refrigerated transport in the milk supply chain expensive. Milk run logistics and dispatch logistics can solve these challenges. Green supply chain management is also optimised routes and vehicle tracking, which minimize the environmental impact while meeting the delivery time.

Pilferage:

Pilferage disrupts the supply chain of the milk industry and results in financial loss and supply disruptions. GPS tracking and cold chain monitoring, two vital components of green supply chain management, cut down theft risks by giving real time visibility. These technologies are a means to increase security in the milk supply chain and reduce losses and maintain product quality.

Data Accuracy:

Dispatch logistics can be optimised, and fuel consumption can be reduced using GPS tracking in the milk supply chain. It ensures efficient milk run logistics, such that delivery is timely without theft through deviation alerts. Cold chain monitoring is improved with real time data, which is consistent with green supply chain management and helps to increase supply chain efficiency and sustainability.

How Does GPS Tracking Software Ensures Fresh Milk Every Time?

GPS tracking in the milk supply chain helps dispatch logistics by routing more efficiently and lowering fuel use. It ensures that milk run logistics are done efficiently such that the milk can be delivered on time, less theft through deviation alerts. Cold chain monitoring with real time data aligns with green supply chain management improving supply chain efficiency and sustainability.

FAQs

1. What is the Milk Supply Chain?

The milk supply chain includes milk production, transportation, processing, packaging and distribution of milk products. It connects farmers and processors to retailers to get fresh, safe milk from farm to retail shelves efficiently while simultaneously adding value at each stage.

2. What are the Stages of Milk Supply Chain?

Production, milk collection, transportation, pasteurisation, packaging and distribution makeup the milk supply chain. For quality, freshness and timely delivery to consumers, each stage of production logistics, manufacturing logistics and cold chain management is needed.

3. What are the Challenges of Milk Supply Chain?

Rising temperatures affect production, high transportation costs, and pilferage. Mitigating these issues and ensuring product integrity requires efficient milk run logistics, cold chain solutions, and green supply chain management practices.

4. How GPS Tracking Software Ensures Fresh Milk Every Time?

GPS tracking ensures better dispatch logistics by reducing route deviations, fuel consumption, and theft. This helps to monitor cold chain and real time communication for freshness and to support green supply chain management for sustainability.